| Property | Value | Test method |

|---|---|---|

| Density of the material | 1.20 g/cm³ | ISO 1183 |

| Tensile strength | 65 MPa | ISO 527-1/-2 |

| Elongation at break | 8 % | ISO 527-1/-2 |

| Modulus of elasticity | 2400 MPa | ISO 527-1/-2 |

| Impact strength (Charpy, no notch) | 55 kJ/m² | ISO 179-1eU |

| Thermal deformation temperature (1.8 MPa) | 100°C | ISO 75-1/-2 |

| Resistance to chemicals | High | – |

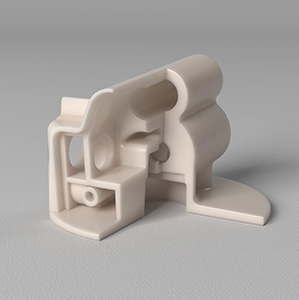

Certified quality

Every manufactured part goes through rigorous inspection to ensure impeccable quality and high precision. Our processes are developed to the highest industry standards, ensuring the reliability and sustainability of your projects.

Our certification to internationally recognised standards is testament to our commitment to quality. Trust our experience and advanced technology to turn your ideas into reality.